Unlike a standard air conditioner, evaporative cooler m […]

Unlike a standard air conditioner, evaporative cooler motors work by drawing dry outside air through moistened pads. As a result, they use less electricity than a standard central air conditioning unit. They are also a cost-effective option for cooling in arid climates, since they do not require the use of refrigerant. Some evaporative coolers also have a fan that moves air into the cooler. It is common to find evaporative coolers with a motor with a capacity of 1/3 to 1 horsepower. However, the motor can vary by brand, model and voltage.

Generally, evaporative coolers have an access panel that is located on the back of the appliance. This panel can be removed by unplugging the wires. This is important because if the wires are not unplugged correctly, they can short out and cause the motor to overheat. The circuitry inside the motor will also be affected if the voltage is too high. It is also important to check the incoming power supply and the wire connection block for proper connections.

Some evaporative coolers are equipped with a run capacitor, which provides additional power to the motor during startup. This can be helpful if the motor is unable to start because of low starting torque. There are also two types of capacitors, one with a main winding and the other with an auxiliary winding. If the capacitor is installed on the motor, the circuitry will be protected from overheating, but if the capacitor is installed on the auxiliary winding, it can be damaged if the motor is overloaded.

There are also several different types of pads that are used in evaporative coolers. These include slit expanded paper, foamed polyester and wood strips. These pads are usually replaced every year when the cooler is de-winterized. Some coolers may require a specific HP or AMP rating. You can find this information online or by checking the owner's manual.

There are two types of shaft bearings used in swamp cooler motors. These are often called squirrel cage shaft bearings. The bearings should be oil-tight. However, they can wear out if the oil is not used. In order to replace these bearings, you will need to disassemble the drive shaft and remove the bearings. If the shaft bearings have an oil port attached, you can fill them with oil.

In addition to the float valve, the swamp cooler may also have a belted fan. The fan belt should be secured properly and not loose or too tight. It may also be necessary to replace the distribution tubing in the cooler. If the tubing is clogged, you may need to remove it to clean it. A common problem with coolers is that the pump is not turned off. To avoid this problem, it is important to make sure the pump is level and the water is flowing evenly across all the pads.

If the fan belt is too loose or too tight, it can cause the motor to overheat. This is also a common problem with swamp coolers. To prevent this problem, it is important to install the correct pulley. This will ensure that the cooler works correctly. The pulley should be the proper size and match the unit.

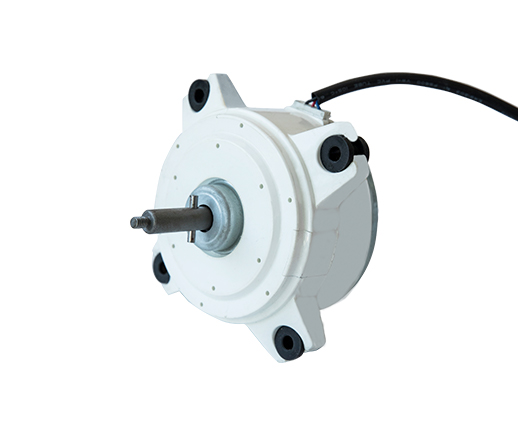

AIR CONDITIONER EXHAUST FAN MOTOR