The noise of different mechanical equipment may be loud […]

The noise of different mechanical equipment may be loud or small, but they should all have normal scale specification values. When the specification value is exceeded, the device may malfunction. What if the DC motor is too noisy?

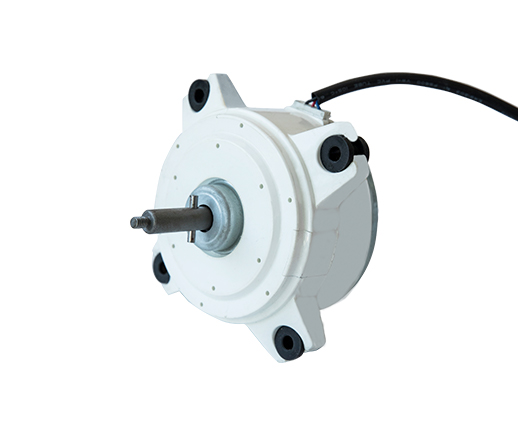

The motor is one of the sources of noise. Motors are widely used in household appliances, automobiles, office equipment, industrial, agricultural and medical industries, and are closely related to people's lives. Therefore, it is the responsibility of every designer and producer to minimize the noise of the motor, produce a motor with low noise, and create a comfortable and quiet living environment for people.

There are many causes of vibration and noise in DC motors, which can be roughly attributed to mechanical noise, electromagnetic noise, and aerodynamic noise.

Noise analysis of DC washing machine motors:

1. Bearing noise. Due to the improper size of the bearing and bearing cavity, the DC motor will rotate with the DC motor rotor and generate noise. Out-of-roundness of the balls or internal mixing of debris can cause them to collide with each other creating vibration and noise. Improper bearing preload values can cause slight vibration and noise on the raceway surface.

2. Noise caused by rotor imbalance.

3. Noise caused by eccentric assembly.

The following methods should be taken to reduce DC motor noise:

1. Pay attention to avoid the resonance frequency of the motor;

2. Use sinusoidal windings as much as possible to reduce harmonic components.

3. Use a rotor chute with a stator slot pitch;

4. The magnetic circuits of the stator and the rotor are symmetrical and average, and overlap closely.

5. Select suitable grooves together to prevent low-order force waves;

6. When processing and assembling the stator and rotor, pay attention to their roundness and coaxiality;

7. Select the appropriate air gap magnetic density, not too high, but too low will affect the utilization rate of the material;

8. Sealed bearings should normally be used to prevent debris from entering.