Cooler Motors achieves more efficient energy use throug […]

Cooler Motors achieves more efficient energy use through a combination of innovative technologies and engineering principles. Here's a breakdown of how Cooler Motors can achieve greater energy efficiency:

1. Advanced power system: Cooler Motors usually adopt advanced power system, such as electric motor, hybrid system or fuel cell. These powertrains are designed to convert energy generated by a fuel source into mechanical motion more efficiently than conventional internal combustion engines. For example, electric motors have fewer moving parts and are able to convert a greater percentage of energy from the source into propulsion.

2. Regenerative braking: Electric and hybrid vehicles equipped with Cooler Motors usually have a regenerative braking system. These systems capture and convert kinetic energy during braking or deceleration into energy stored in the battery. This reduces wasted energy that would otherwise be lost as heat in conventional braking systems.

3. Optimized energy management: Cooler Motors incorporates sophisticated energy management systems to control energy distribution and optimize energy usage based on driving conditions, road gradient and user input. These systems ensure energy is delivered efficiently when needed, saving energy when demand is low.

4. Lightweight materials: Cooler Motors may use lightweight materials in vehicle manufacturing to reduce overall weight. A lighter vehicle requires less energy to accelerate and maintain speed, contributing to greater energy efficiency. Materials like carbon fiber, aluminum and high-strength steel are often used to reduce weight while maintaining structural integrity.

5. Streamlined Design: Efficient vehicle aerodynamics help reduce air resistance, making the vehicle require less effort to move through the air. Cooler Motors may feature streamlined designs and aerodynamic enhancements such as streamlined body shapes, chassis panels, and active cooling grilles that help reduce energy consumption at higher speeds.

6. Efficient thermal management: Cooler Motors carefully manages the heat generated during operation. An efficient thermal management system ensures that components operate within an optimal temperature range, reducing energy loss due to excess heat. This extends component life and improves overall system efficiency.

7. Smart Electronics and Control Systems: Advanced electronics and control systems play a vital role in energy efficiency. Cooler Motors may incorporate predictive algorithms, machine learning and real-time data analytics to make informed decisions based on power distribution, energy usage and component performance.

8. Energy-efficient components: Cooler Motors uses high-quality, energy-efficient components such as power electronics, inverters, and batteries. These components are designed to minimize energy losses during energy conversion, storage and distribution.

9. Integrated heat and energy recovery: Cooler Motors may employ integrated thermal management and energy recovery systems to capture waste heat from individual components and use it for other tasks such as heating the interior of the vehicle or improving engine efficiency.

10. Ongoing Research and Development: The manufacturer of Cooler Motors is constantly investing in research and development to further improve energy efficiency. This includes exploring new materials, optimizing existing technologies, and developing new solutions to optimize energy use in various operating conditions.

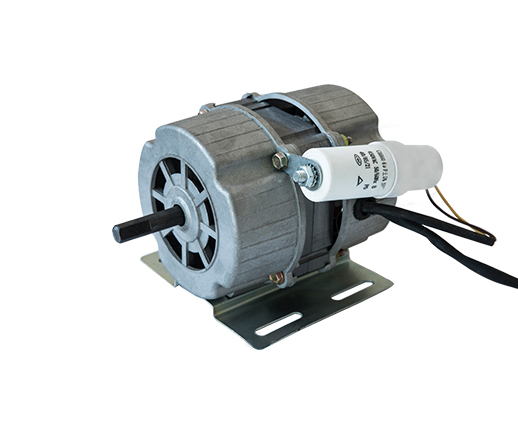

Outdoor Fan Motor For Air Conditioner