1.Improved Motor Design: Modern cooler vehicles priorit […]

1.Improved Motor Design:

Modern cooler vehicles prioritize quieter operation via meticulous layout and engineering. These automobiles frequently characteristic specialised insulation substances that successfully soak up sound waves generated all through operation. Additionally, manufacturers utilize vibration-dampening materials strategically located within the motor shape to lessen the transmission of vibrations that could contribute to noise. These layout elements work in tandem to limit the motor's contribution to universal refrigeration gadget noise.

Furthermore, advancements in precision engineering allow manufacturers to optimize the motor's internal components for smoother and quieter operation. This includes the implementation of high-quality bearings, making sure minimum friction and noise technology. Engineers additionally cognizance at the motor's airflow layout, enhancing fan blade sizes and styles to enhance cooling performance at the same time as simultaneously lowering noise tiers. Such adjustments aim to strike a delicate balance between finest overall performance and minimum acoustic disturbance.

2.Balanced Fan Blades:

The layout and balance of fan blades extensively impact the noise ranges produced by using cooler vehicles. Imbalanced blades can cause irregular rotations, leading to vibrations and improved noise. To counter this, producers meticulously engineer and balance fan blades to make certain they perform easily and flippantly. Advanced production strategies are employed to gain particular blade symmetry, minimizing disturbances that contribute to noise generation.

Balanced fan blades not simplest lessen vibrations however also make certain that airflow stays constant and uninterrupted. This consequences in a quieter cooling device basic, especially whilst coupled with other noise-reduction measures.

3.Variable Speed Motors:

Cooler cars ready with variable velocity manipulate provide a superb advantage in noise discount. These cooler motors can alter their speed primarily based on cooling needs, running at lower speeds throughout intervals of lower temperature necessities. By going for walks at decreased speeds, variable pace automobiles produce much less noise compared to fixed-speed vehicles that continuously function at most capability.

The capability to modulate motor speed not best saves strength however also contributes appreciably to noise discount. By minimizing the motor's workload all through periods of decrease demand, variable speed motors preserve quieter operation even as making sure green cooling while necessary.

4.Efficiency and Reduced Friction:

Efficiency in cooler automobiles not handiest interprets to electricity financial savings however additionally contributes to noise reduction. Advanced motor technology, which includes brushless DC vehicles, produce much less warmness and friction throughout operation compared to older motor types like brushed cars. This reduction in warmth and friction inherently results in quieter motor overall performance.

Brushless DC cars make use of digital commutation instead of brushes, putting off the physical contact that could generate noise in brushed automobiles. Moreover, the layout of brushless vehicles permits for smoother and extra managed rotation, in addition reducing operational noise.

5.Isolation Mounts:

The incorporation of isolation mounts or rubber grommets between the cooler motor and the refrigeration system's structure serves as an effective technique to hose down vibrations and reduce noise transmission. These mounts act as buffers, soaking up vibrations generated by means of the motor and stopping them from shifting to the surrounding additives or the equipment itself.

Manufacturers strategically function these isolation mounts to isolate the motor from the system's chassis, thereby mitigating the propagation of noise. The use of such isolation strategies considerably contributes to developing a quieter working surroundings for refrigeration structures.

6.Maintenance:

Regular protection is vital for making sure that cooler motors operate at their choicest overall performance degree, which includes minimizing noise output. Lubricating shifting parts inside the motor reduces friction, stopping excessive wear and noise era. Additionally, well timed substitute of tired additives which include bearings or belts allows hold the motor's performance and quiet operation.

Regular inspection and maintenance routines are essential to discover and address ability assets of noise before they strengthen. By adhering to a proactive renovation schedule, corporations can uphold quieter operation in their refrigeration equipment, making sure a extra snug and conducive surroundings.

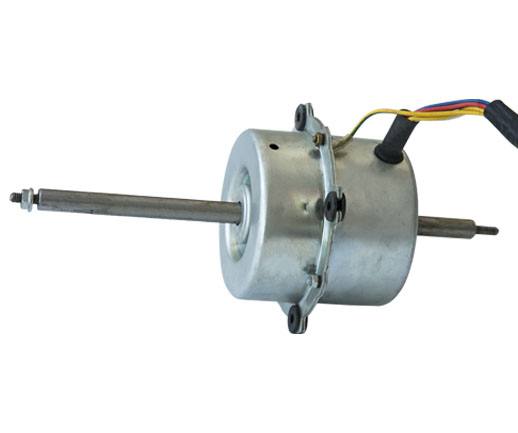

Single Phase AC Air Conditioner Motor