Have you heard of the type of washing machine motors?Th […]

Have you heard of the type of washing machine motors?These motors include: inverter motors, brush motors, BLDC motors, and garden variety motors. While all of these motors perform the same task, there are some differences between them.

Inverter motors

Inverter motors are used in modern washing machines. They have numerous advantages and they tend to cost less than ordinary motors. The main difference between an ordinary motor and an inverter motor is the type of drive. The latter is more precise and requires less electricity to run. An ordinary motor will turn and slow down based on an external network. This means that an inverter motor does not have to constantly monitor its engine speed. As a result, it will cost between 10 to fifteen percent less to operate a washing machine than an ordinary motor.

Another major difference between a conventional washing machine and an inverter one is the speed of the motor. The inverter motor has a variable speed and can be adjusted according to the load. This saves a significant amount of electricity and minimizes noise.

Brush motors

When you choose a brush motor for your washing machine, it is important to choose the right one for your needs. These motors are designed to agitate the drum in both forward and reverse directions. They also have the capability to operate at high speeds needed for the spin cycle. These motors are ideal for domestic machines.

A brushed DC motor works by supplying electric energy to its coils through fixed brushes. A commutator attached to the rotor then reverses the polarity of the current and flips it inside the motor. Different types of brush motors work in different ways, with one type of motor using a fixed brush while another uses a rotating commutator.

Garden variety motors

A common cause of washing machine failure is a motor. Despite the popularity of electronic speed controls, many domestic washing machines still use a manually operated motor. These motors have the power and flexibility to perform a variety of tasks, including spinning the clothes. A typical top-loading washing machine uses a motor that rotates in one direction. When the timer is triggered, a solenoid engages a clutch that locks the motor rotation to the wash basket. A variation of this design is the Filter-Flo line of washing machines, which used a motor that reversed only to pump water out.

BLDC motors

BLDC washing machine motors use built-in electronics to control the motor's speed. They are used in washing machines to reduce overall noise levels. The motors in Samsung washing machines, for example, feature an internal microprocessor to control the speed. A BLDC motor is a more reliable option for washers. In addition to these advantages, BLDC washing machine motors are also less noisy than conventional motors.

A BLDC motor has two major components: a stator and a rotor. The stator, or stationary part of the motor, is made up of copper windings and permanent magnet sheets. This copper winding produces the magnetic field, which rotates the rotor. The rotor, or armature, is a rotating permanent magnet that is made up of soft-iron sheets with slots. When the rotor rotates, it produces an induced voltage which causes a torque on the rotor shaft.

Belt drive motors

Traditional washing machines use a belt drive system to rotate the drum. The belt transmits power to the drum, which rotates in both the clockwise and the anti-clockwise directions. However, this belt is prone to wear and tear and will eventually need to be replaced. Another drawback of a belt drive system is the noise it produces.

Belt drive motors in washing machines can reduce noise during operation by reducing the motor's torque. This can be accomplished by reducing the torque in washing and spinning modes. This also reduces the belt's tension and can also reduce motor startup torque requirements.

DC diac/triac circuits

To control the speed of a washing machine motor, a DC diac/triac circuit is used. The diac is powered by a capacitor C4. This capacitor acts as a current limiter by limiting the amount of energy that the motor can receive. It also controls the energizing angle of the triac T.

The capacitor C4 is charged to a gentle starting condition when fed llOV. The charging current of the capacitor is proportional to the speed of the motor.

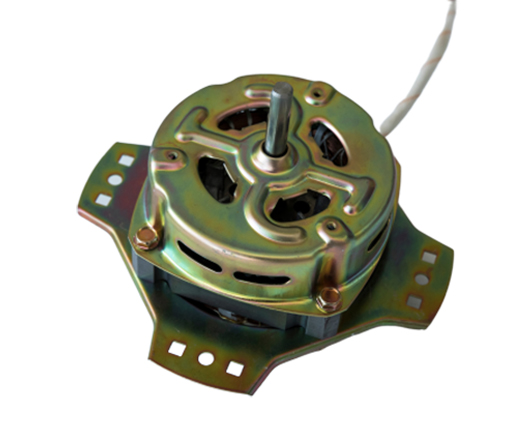

70W 4 LEGS SPIN WASHING MACHINE MOTOR

Our company insists on the belief of "Good Quality, Definite Credit-Standing and Timely Innovation" and exerts ourselves to build the special culture and good public image of the enterprise. With advanced management idea, we updated the system, employed a lot of professional technologists, purchased advanced production equipment and expanded international market thus have made rapid progress.